KWS in figures

Founded in

Subsidiaries and associated companies

Employees

SALES

EBIT

Seeding the future – since 1856

KWS sows the future. Our high-yield seeds and extensive knowledge make us a trusted partner of farmers - and we have been for generations. In this way, we contribute to solutions for the nutrition of a steadily growing world population. We are constantly improving genetic potential through excellent research and breeding programs. With our high-performance seeds for corn, sugarbeet, cereals, vegetables, oilseed rape, sunflowers, catch crops and many more, we offer a wide range of products that meet the most diverse requirements in temperate and tropical climates and enable balanced crop rotation. We tailor our seeds to the needs and requirements of our customers to deliver the very best quality, and we are a strong partner throughout the value chain.

Vision

Seeding the future for generations

Our vision comprises all of KWS key values – With foresight, we shape a sustainable future, staying close to generations of farmers and serving as a trusted, reliable partner to all our customers while staying independent as a family-owned company.

Mission

Our passion for plants sustains farming, food and planet

We are convinced that our specialization in plant breeding and seed production makes a difference. We breed and research with passion - and thus makes an important contribution across the entire agricultural production. This impactful work goes beyond increased yields: Through varieties with relevant characteristics such as drought resistance or reduced plant protection requirements, we create solutions and support agriculture in successfully addressing the challenges of the coming years.

KWS seeds are at the very start of the food chain. We bring our expertise and passion forward into the entire farming value chain and beyond. We think in terms of our customers and their customers: Which variety properties are relevant for further processing of the crop and the final product and how can plant breeding already enable this? We think in terms of our planet: With focus on the reduction of inputs such as crop protection products or water, innovations for alternative energies and, of course, the efficient use of available land represent a contribution to sustainable agriculture of the future.

With our services (via consulting and digital tools), we help farmers get the most out of our seeds on healthy soils. Our broad and growing portfolio of crops and vegetables provides a foundation for preserving biodiversity in the fields. Through our daily work, we make an important contribution to the supply of good food to our growing world population. And that is what we are proud of.

Values

Closeness

For us, togetherness arises from human closeness. And this is based on personal appreciation. Both to motivate and inspire. This is how we create our very own team spirit, which we also show to the outside world. The farmer’s ability and our generation-spanning connection is the foundation of our success. By involving farmers and exchanging information on a partnership level, we learn from each other and grow together. As understanding team players, we face the farmer in an honest manner and at eye level. We respect them and focus on their needs.

Reliability

KWS is a company with a tradition of family ownership, and we operate in that spirit. Our decisions and actions are transparent, reliable and immediately comprehensible. Both internally and externally, we are pragmatic and authentic, fast and uncomplicated and we deliver the best seed. This is our contribution to the farmer‘s success. They expect transparency and reliability, against which they also measure our credibility. If we fail to meet this standard, we solve problems honestly, immediately and in an uncomplicated manner.

Foresight

Only by acting wisely the world's food supply may be secured. That is why our employees develop innovative solutions for various cultivation conditions. High and secure yields for the farmer always remains the goal, and optimized plant breeding is the central means of achieving sustained growth. We are unbiased in our approach to future challenges in agriculture, whether climatic or regulatory, and we invest sustainably in research and breeding. By remaining responsible towards people and nature, together we shape the future of KWS for an agriculture of various cropping systems.

Independence

KWS is a company specialized in seeds. Managed independently for generations, it acts according to the same standards farmers do: Independently, free in choice and prudently. Our employees think and act with entrepreneurial conviction. Enthusiasm for agriculture is what drives them. We demand and promote their freedom and encourage them to act under their own responsibility.

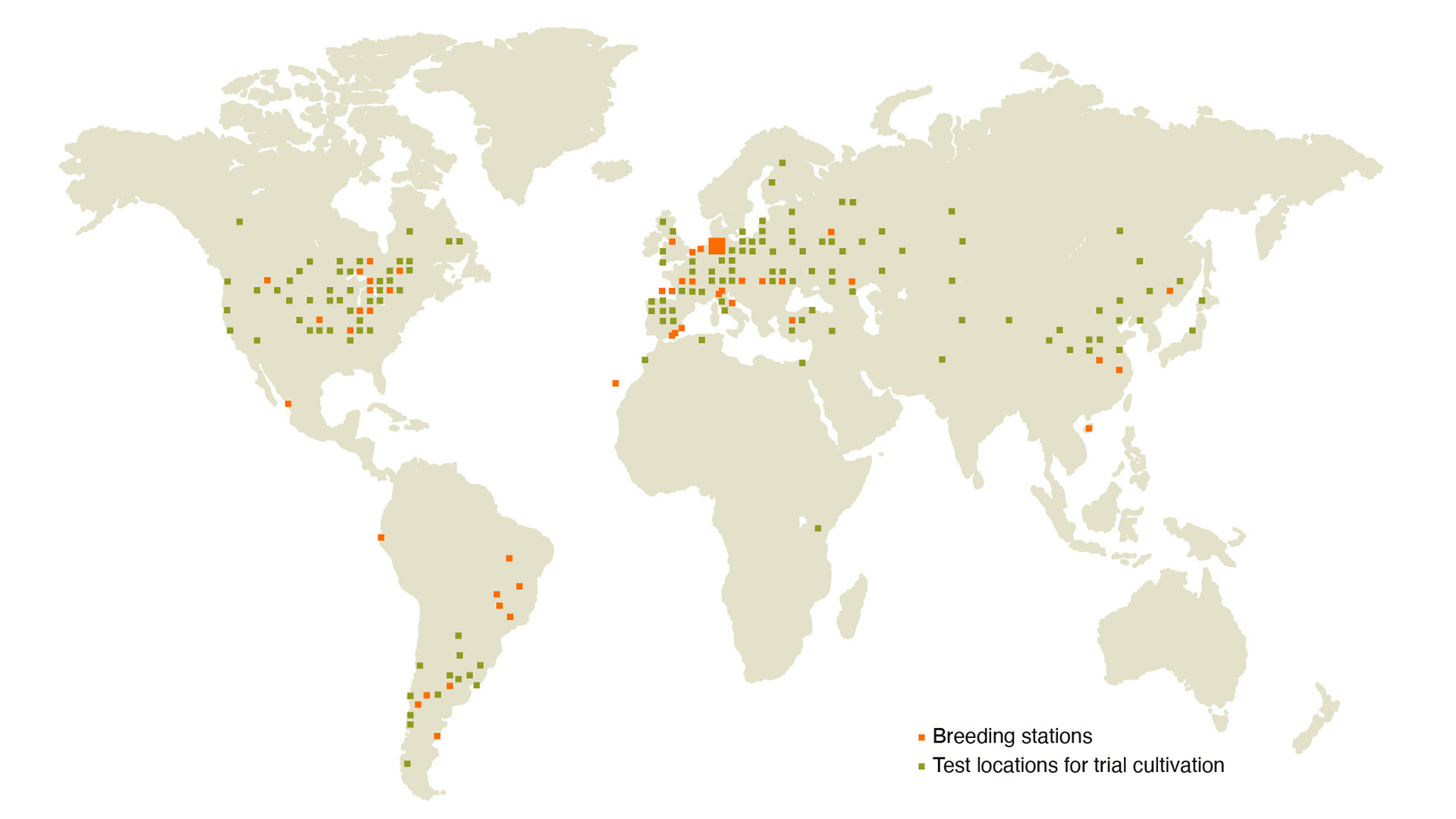

Active in more than 70 countries worldwide

KWS SAAT SE & Co. KGaA is the parent company of the KWS Group. It is a strategic leader and handles, among other things, the breeding and propagation of sugar beet and maize seeds. The company finances basic research and the breeding of a diverse range of varieties in the KWS Group and annually supplies its branches with new varieties for propagation and distribution.