The highlight of every season: Harvesting

For every farmer, harvesting is labour-intensive but also satisfying. After a long period of growth and development, we finally reap what was sown. There also there are different procedures and aspects to consider for each type of crop.

Maize can be harvested as grain maize and silage maize for animal feeding or as a substrate for biogas plants. Whereas silage maize for animal feeding and biogas maize are harvested in the same way, grain maize harvesting differs fundamentally from them.

KWS has summarised the most important differences concisely for you.

Various uses - different harvesting methods

The grains obtained from harvested grain maize are suitable for animal feeding and human nutrition. To obtain the driest possible harvested material, the grain maize is harvested at the end of the vegetation period. Combine harvesters adapted to the requirements of grain maize harvesting are used for this purpose.

Harvesting of grain maize can be characterised by the following features:

- Harvesting is performed with a combine harvester at the end of physiological maturation and at about 35% moisture in the grains

- A special grain maize harvesting attachment is required (so-called “Maize header”)

- The goal: a low grain moisture (at least below 35%, preferably <30%) to achieve lower drying costs

- Low fractions of broken grains, to achieve a high fraction of marketable goods

- At a grain moisture of less than 30%, Dent x Dent hybrids exhibit better water release, a process known as dry-down. In this way, dryer grain maize can be harvested at favourable locations. However, water release starts later than in Dent x Flint hybrids, which are somewhat better adapted to Northern European climates.

The harvesting methods for silage maize for animal feeding and energy maize as a substrate for biogas plants do not differ from one another. Only the criteria for variety selection are different.

In silage maize, almost all of the above-ground biomass is harvested using field choppers. The optimal harvesting time depends on the DM content of the whole plant and is between 30 – 35% DM.

Both premature and delayed harvesting dates have negative consequences for yield, quality and ensilability of silage maize.

Therefore the optimal Harvest date has a great effect on success in silage maize cultivation. The CultiVent Tool DM Monitoring helps you find the optimal harvest date and thus achieve optimal yields and qualities.

Do you produce maize silage? Our Silage Manager shows the most important points for producing excellent silage quality. Also look at points to be considered in the case of Storage in the silo .

Stubble processing after the maize harvest

Intensive working of the stubble and soil after the maize harvest is a very good measure for maize borer control and for combating fusariosis in the subsequent crop. Various experiments have shown that the use of mulchers after harvesting maize can substantially reduce both the number of maize borer larvae and the incidence of fusariosis in the subsequent crop. The reduced incidence of fusariosis also significantly minimises the risk of excessive DON contents, for example in a subsequent crop of winter wheat.

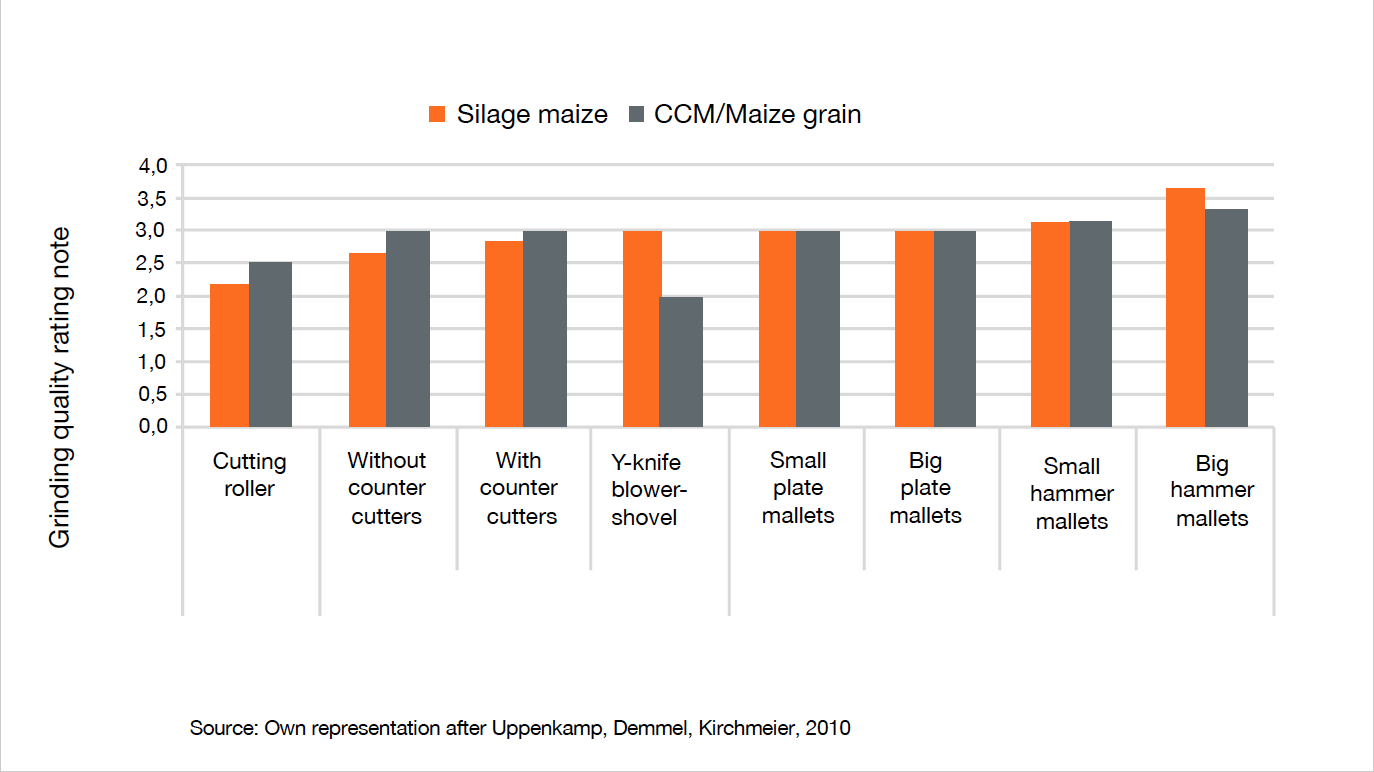

For this reason, intensive comminution of the maize stubble is especially important. The graph below illustrates the comminution quality of various mulchers.

As you can see in the graph, there are definite differences in the comminution quality of maize stubble with various mulchers. In this experiment, the flail mulcher with large hammer flails gave the best results.