The silaging process is of immense significance!

Especially in dairy cattle feeding and cattle farming maize silage is an important feedstuff: It is cost-effective to produce, delivers high energy levels and is excellent for storage, to ensure year-round supply.

Silage preparation seeks to achieve the following:

1. Contain nutritional values

- The nutritional value of the silaged food remains intact.

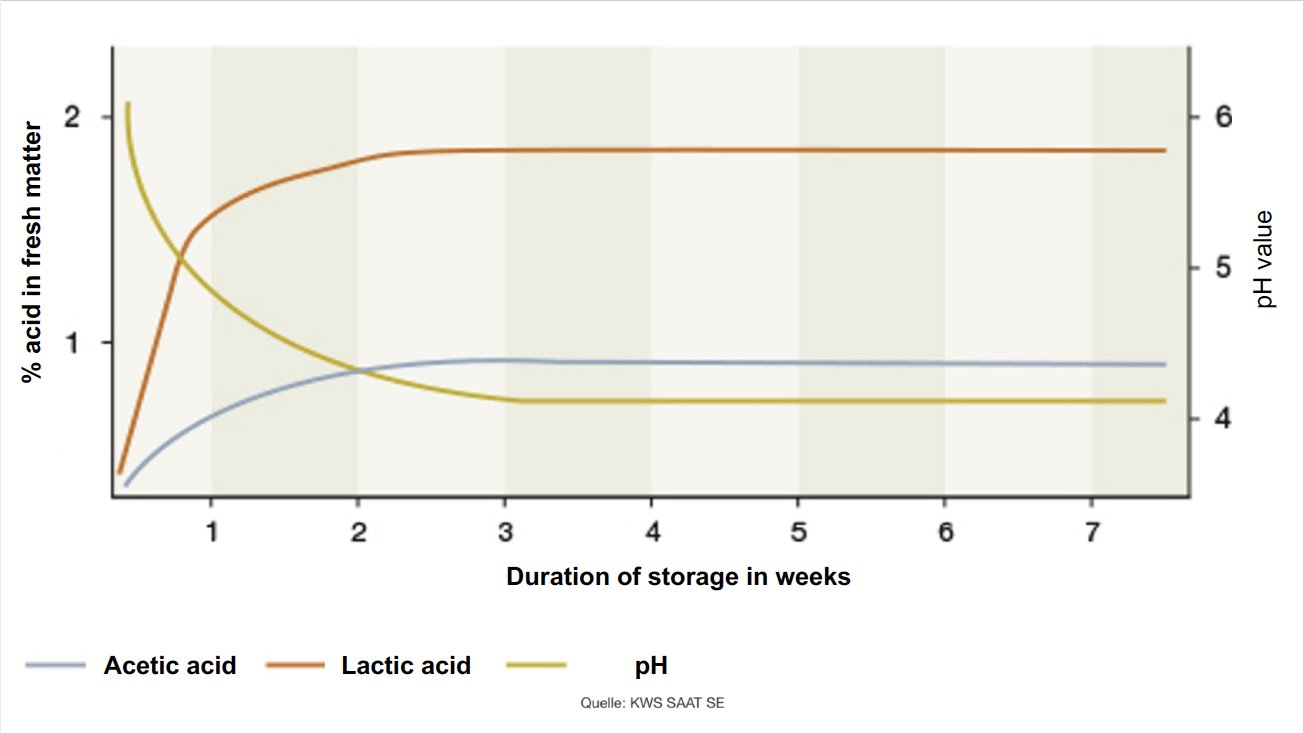

- Lactic acid bacteria transform plant-based carbohydrates into organic acids.

- The resulting acids result in the dropping pH-value.

Depending on the dry mass of the maize silage, this should be as follows:

Fresh maize: pH 6.5 - 7

<30 % TM: pH <= 4.0

>30 % TM: pH <= 4.5 - The low pH-value preserves the silo and makes the silage storable for a long time.

2. Identifying losses

- Optimal silage processes are seen to be those with loses of 5 to max. 10%, depending on the fermentation acid progression of the silaging.

- The pure lactic acid fermentation is lossless. For acetic fermentation, DM losses of approx. 5% result.

3. Avoiding losses

- The acetic acid fermentation should despite higher silaging losses always be involved to a certain extent, as acetic acid promotes aerobic stability and therefore prevents higher losses in the silo extraction.

- All process-dependent and avoidable losses during the harvest and removal must be avoided.

Energy losses in silaging

Resulting energy losses in the silaging process are distinguished by being "unavoidable", "procedure-dependent" and "avoidable". The following table shows the loss of net energy during silaging:

| Loss cause | Assessment | Energy losses (%) |

| Residual breathing | unavoidable | 1 - 2 |

| Fermentation | unavoidable | 4 - 10 |

| Silage effluent | depending on process | 0 - 8 |

| Field losses | depending on process | 1 - 5 |

| Faulty fermentation | avoidable | 0 - 10 |

| Aerobic spoilage (in silo) | avoidable | 0 - 10 |

| Reheating (at removal) | avoidable | 0 - 10 |

Source: KWS SAAT SE & Co. KGaA