On the journey from seed to beet

Did you know that the production of our high quality seeds involves hundreds of steps?

Complexity and modern science is needed to launch a new variety to the markets and ensure the best technology and better yields for sugarbeet farmers.

Become an expert by exploring our 4 key topics

Breeding

Did you know that KWS was born with sugarbeet breeding?

With more than 165 years of sugar beet breeding experience “KWS was born with sugar beet breeding”. It takes 10 years of selection efforts to provide the market with a new sugar beet variety. To make this process faster we are looking into new breeding technologies to potentially reduce this process by 2-3 years. Currently there are 18 breeding stations worldwide with more than 360 professionals working in Research & Development on more than 50 ongoing sugar beet specific projects. Each year 100,000 single plants are selected, 10,000 inbred lines are grown and worldwide around 100 varieties get approved to the markets.

BREEDING EXPERIENCE

NEW BREEDING TECHNOLOGIES

ANNUAL YIELD INCREASE

PROFESSIONALS IN R&D

PROJECTS

APPROVED VARIETIES

Processing

Did you know that a sugar beet seed is processed 6 times until it is ready to be delivered?

Production

Immediately after the harvest (from mid-July to the beginning of August), the seed is pre-cleaned in the production regions of Italy and France. If necessary, it is carefully dried to a humidity of less than 10 % and stored. After the pre-cleaning process, the seed lots are cleaned according to priorities in the facilities in Italy or France and shipped to Einbeck.

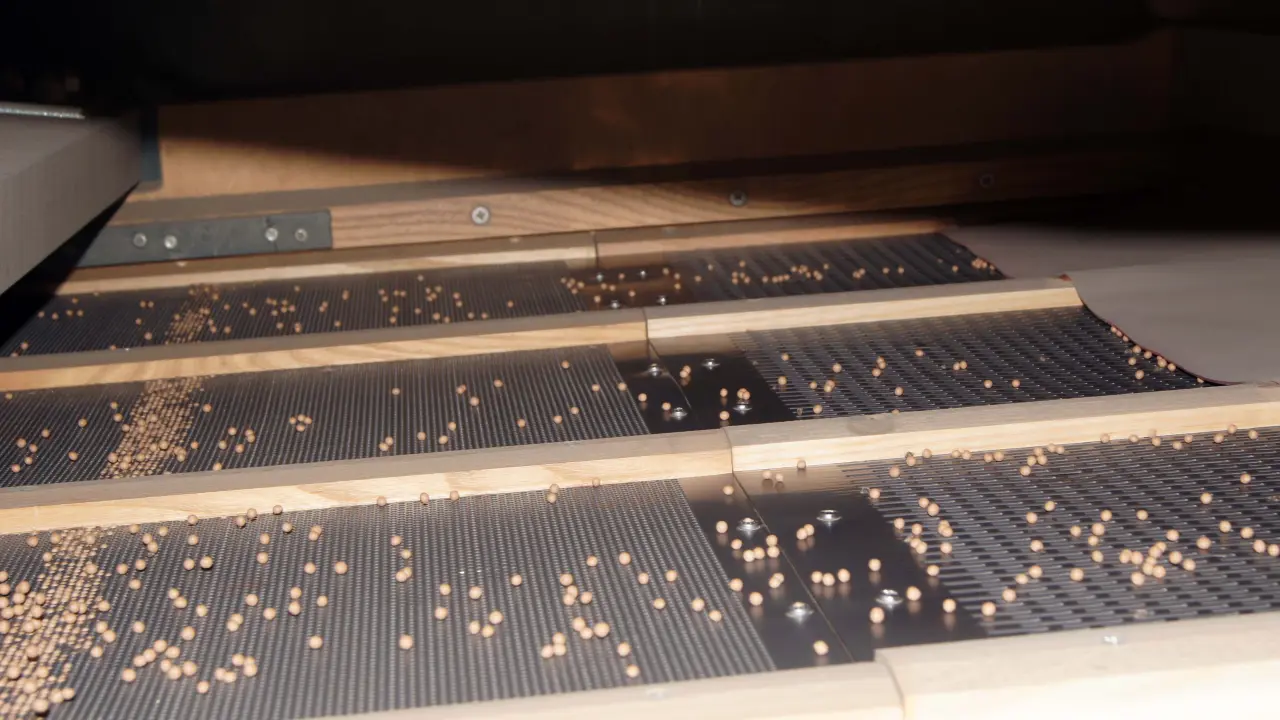

Seed processing in a computerized plant

The first step of seed processing is the sizing of the seed into several different fractions. Afterwards, each size is polished individually to remove excessive pericarp (lignified structures) containing substances which inhibit germination, and to give the seed a better spherical shape.

Pelleting

After successful processing, the irregularly, flat bare seed is coated with a pelleting mass. This mass serves as a base for the application of fungicide and insecticide substances and improves the sowability of the seed (precision seeding).

Treatment and color application

The active substances are applied in a computerized new plant by rotor technology. As a first step chemicals are applied on the surface of the pelleted seeds. Afterwards, the application of the KWS specific orange color follows.

Quality Assurance

Did you know that 54,000 samples are taken a year to conduct more than 420,000 quality tests?

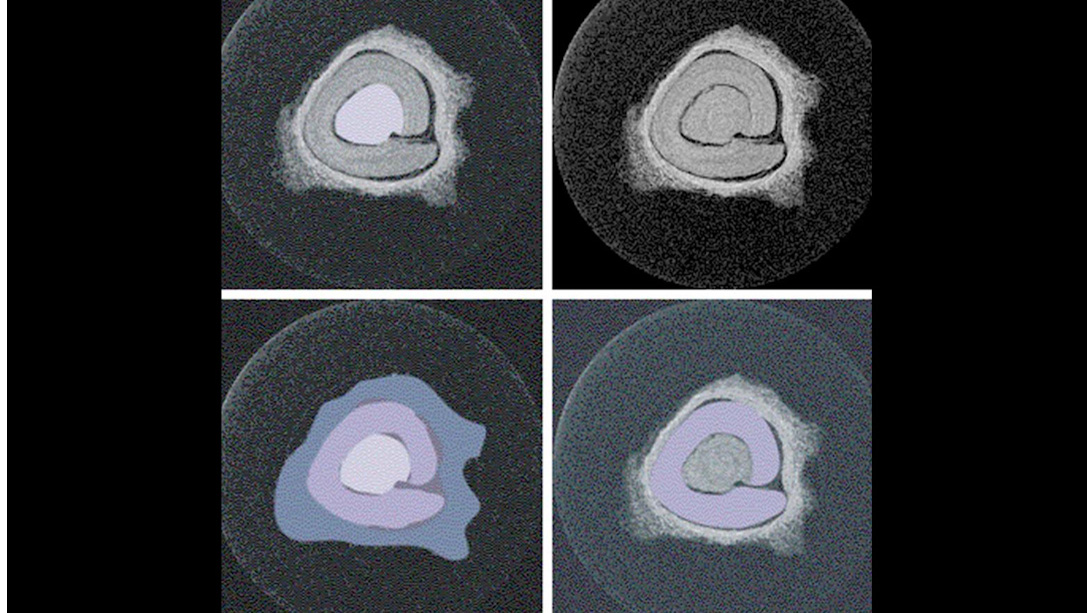

Empty seeds and seeds with deficient embryos are removed in a combination of airstream and gravity-separation by the specific weight of the single seeds. Only perfectly polished seed with fully developed embryos will guarantee high field emergence especially when difficult environmental conditions prevail. There are 54,000 samples taken to conduct a total of 420,000 quality tests each year to provide high quality seeds to the farmers.

Packaging

Did you know that we produce more than 6 million KG of seed pills per year?

Before the seed is delivered to the sugar factory or the farmer, the finished product is packed in units, which is done based on the thousand seed weight in an automated packaging plant. In the last fiscal year we packed more than 6 million KG of beautiful orange sugar beet pills into boxes.

.jpg)