How the variety choices you make can effect the carbon footprint of your crop production

Reducing carbon through the crop growing cycle is a minefield for UK arable producers with the only certainty being that it’s a goal that will increasingly lie at the heart of many business decisions in the future, says Dr. Kirsty Richards of KWS UK.

“We are all wrestling with exactly what the implications of reducing carbon are for UK growers and whilst much of the debate hinges around the obvious need to reduce inputs and manage energy use better, in reality it’s much more nuanced than that.

“Livestock production has its own set of problems, but in arable production the recurrent areas revolve around using Nitrogen more efficiently, being mindful of the carbon footprints of products and inputs used and supporting on-farm renewable energy more.

“But there are other key factors which are often overlooked, such as reducing food waste and the role of productivity in the carbon equation.

“If you halve your carbon footprint, for example, but halve your production too, then the carbon footprint per tonne of production stays the same, so you can argue that’s not really addressing the issue.”

Part of KWS’ ‘Sowing for Peak Performance’ (SPP) initiative is to look at the challenges growers will face in the next 10 years and focus current knowledge sharing and future breeding strategy on these issues, she explains.

“80% of the results you will see at harvest are locked into the seed that you sow. You can finetune this with good management but by and large genetics dictate the overall potential of the crop.

“The characteristics of the crops you grow and the varieties you choose can also affect your carbon footprint in a way we are only just starting to understand.”

1. Don’t dismiss yield

Whilst the recent direction of travel has been to focus on functional traits and agronomic features that make crop production easier to manage and more consistent, producers dismiss the future role of outright yield at their peril, says KWS UK country manager Will Compson.

“It’s absolutely essential that we breed varieties that are more resilient and can cope with the wider variations in growing conditions that are likely to be experienced as a result of climate change.

“But it’s equally essential that these varieties deliver financially. The more tonnes you produce from a finite set of resources, the lower your cost of production per tonne and I think this is the way we need to be thinking about in terms of carbon footprints.

“If you can produce 20% more yield from the same resources using one variety rather than another, that’s going to improve your carbon efficiency significantly.

“The last thing anybody wants is to drastically reduce the output of UK arable production so in most years we are a net importer of grain. The food miles in that alone are likely to outweigh any carbon benefits we have made in the production of crops.”

Real benefits result when varieties are able to produce more from lower levels of carbon-intensive inputs, he says.

“We’re already on that journey. The Group 4 hard wheat KWS Cranium, for example, has the best yield, OWBM and yellow rust combination of all hard feed varieties on the 2021/22 AHDB RL and there are many more with similar features currently in the pipeline.

Frontier seed manager Chris Piggott, says KWS Cranium is a great example of a ‘new generation’ variety capable of reducing production risks without sacrificing yield potential.

“It’s already yielding within 1% of the highest yielding variety on the Recommended List and is part of a select few varieties that combine a Septoria score of 6 and above and a yellow rust score of 8 and above.

“These two particular diseases are the most challenging in terms of yield penalty so to have high genetic resistance is a real advantage.”

80% of the results you will see at harvest are locked into the seed that you sow

2. Use disease resistance wisely

Disease resistance is an easy one to square up in terms of improving the carbon footprint of production, says Dr. Kirsty Richards.

“KWS Extase achieves an untreated yield of over 10t/ha in the 2021/22 RL and scores 8.0 for septoria resistance so many people are thinking how they can cut back on fungicides and applications.

“The less you have to spray, the less diesel you’re going to be using and, of course, fungicides themselves are fairly energy-intensive to produce and there’s all the transport involved as well.

“I think it’s fair to assume the more disease resistance we build into varieties the less dependent they will be on fungicide programmes and the better that is for carbon footprints.”

Independent agronomist Bob Simons agrees saying many growers are already finding they can cut out one spray application with KWS Extase.

“There’s little evidence of Extase benefitting from ‘heavy duty’ spray programmes anyway, but a lot of people have found the variety does not need a T0 spray, unless yellow rust is prevalent. Just a low cost triazole does the job, if needed.

“A modest triazole with a sensible SDHI can manage most situations at T1 although it’s a good idea to apply something half decent at the T2 timing.

“But we need to be careful. Genetics and chemistry have to increasingly work together in the future and that’s really where people have seen the biggest gains with Extase.

“The longer we can protect the genetics and avoid diseases becoming resistant to actives the better.”

There are significant gains to be made by not using high levels of energy to plough or subsoil

3. Match variety to cultivation method

Min till and no till cultivation methods are becoming increasingly popular but the varieties you choose for these can have a big effect on the success of the system, KWS trials are showing

“There are significant gains to be made by not using high levels of energy to plough or subsoil,” Kirsty Richards says.

“But the downside is often poorer yields which again potentially increases the carbon footprint per tonne of production.

“Our latest trials suggest wheat varieties suited to later drilling could be the best bet for growers transitioning to no till systems and provide greater protection against climate extremes.”

The trials compared fully ploughed cultivation systems to no till across a range of popular varieties with KWS Extase and KWS Cranium, both later drillers with comprehensive disease resistance packages, producing the highest yields,” she explains.

“Although the Group 2 variety KWS Extase was the highest overall yielder in both ploughed and no till scenarios, Group 4 KWS Cranium was the highest yielder affected least by type of cultivation system.

“These were also the varieties that bounced back the strongest after the challenging establishment conditions typified by the last two autumn drilling seasons.”

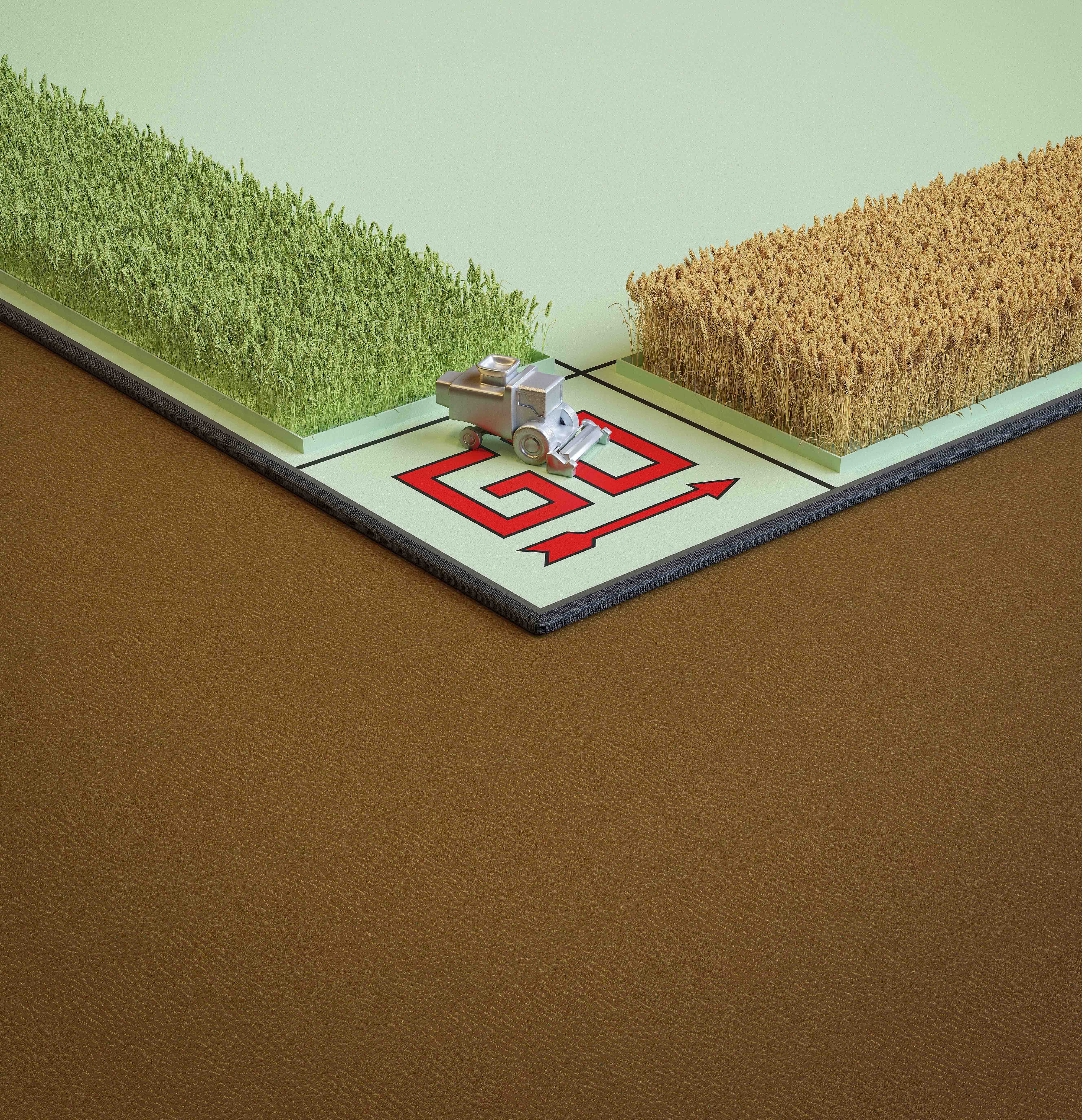

4. Focus on variety scheduling

Modern varieties have so much to offer it’s tempting to make decisions on them in isolation but the real benefits of modern breeding are only fully realised when you integrate key traits into a schedule taking into account varietal performance throughout the year, she says.

“Using highly Septoria resistant varieties like KWS Extase and KWS Firefly is always a good starting point but you can use a variety like KWS Cranium in later slots, for example, to create different management options throughout the growing season.

“Managed properly, you can create wide spray windows through the year to spread workload at key timings, bring them closer together for simpler, quicker management or mix and match intervals for sprays to suit individual farm workloads.

“In addition, you can ensure chemistry is applied at precisely the right time to get the best response from it so, combined with disease resistant varieties, you can optimise spray costs and disease control.

“And the same is true with harvest date. Depending on your rotations, you can use variety and drilling date to create an early harvest, a more compact one or spread it out over the summer to reduce pressure on machinery.

“So if you get your variety portfolio and scheduling right, chances are you’ll be using your chemistry more effectively, reducing applications and cutting back on diesel costs. All of which can significantly reduce your carbon footprint.”

5. Protect your soils

Systems of production that are kinder to soils than current ones have to be a priority in a more carbon friendly future, she adds.

“Reducing compaction through excessive machinery travel is key but we will also have to focus on nutrition practices that build organic content.

“More vigorous varieties that exert greater competition against weeds can reduce the need for heavy duty cultivations, and later drillers can help by giving enough time to deal with blackgrass and other weed problems before they need to be drilled.

“KWS Firefly can be drilled from the start of September to the end of February, for example, giving plenty of opportunity to drill only when the soils are in good enough condition to support it.

“Spring wheat varieties have come a long way in recent years and add further options, so in really bad autumns you can move a significant part of your drilling to the new year with the yield losses previously experienced.

“Early harvesting varieties like KWS Parkin, with its potential July harvest date, can also extend the cultivation and drilling window to help you avoid having to work on land when soils are not in their best load-bearing condition.

“Soils are critical stores of carbon and a vital component of carbon sequestration for the future.

“The better heart they are in, the more effective they are and the varieties you choose and how you manage them can have a profound effect on this.”

Five key points

Don’t dismiss high yields – higher yields dilute carbon footprints per tonne of production

Use disease resistance wisely – opportunities exist for cutting back on chemistry and energy

Match variety to cultivation method – choose later varieties to maximise performance in min till situations

Focus on variety scheduling – optimise ‘windows’ to work more efficiently

Protect your soils – use varieties strategically to minimise travel

Your consultants